High-quality metrology for quality control in the measuring room, production, incoming goods and development.

Gear Metering Pumps & Meter Mix Dispense Machines with highest accuracy for processing liquids and pastes.

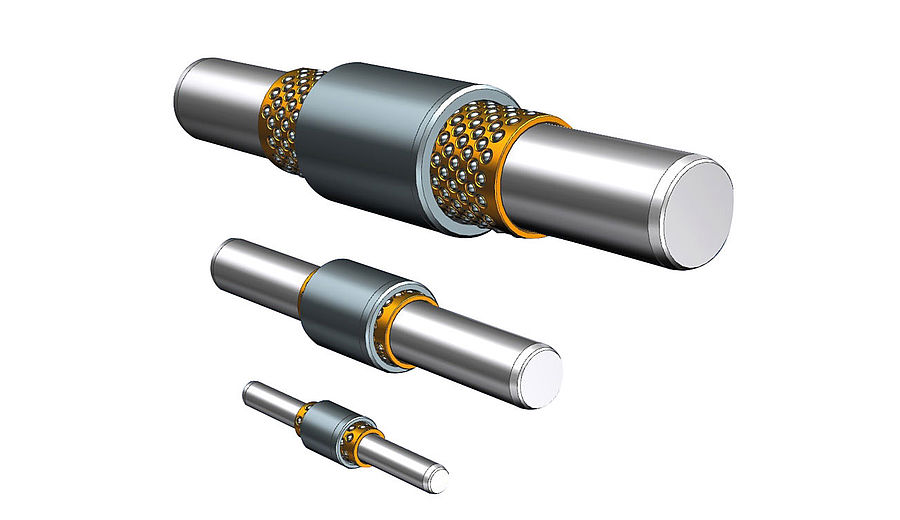

High-precision rotary stroke bearings for backlash-free linear and rotational movements for use in machine and device construction.

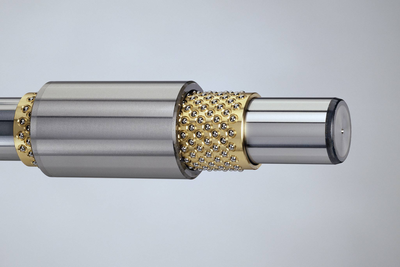

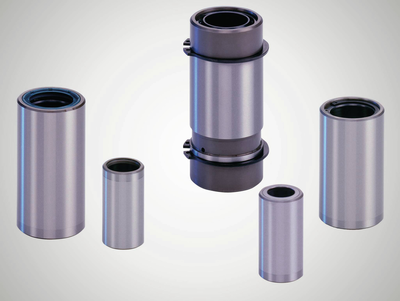

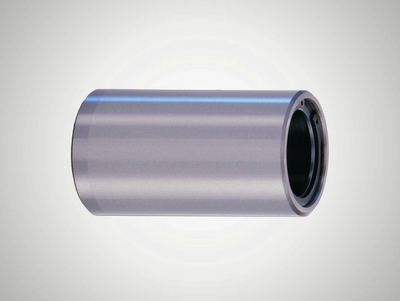

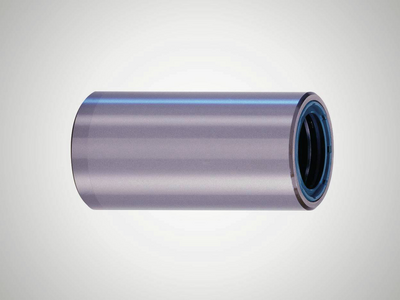

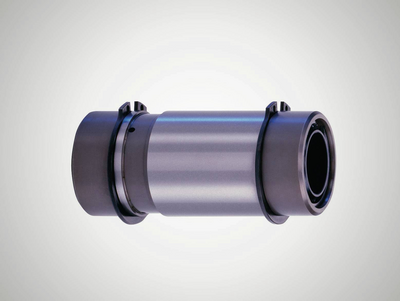

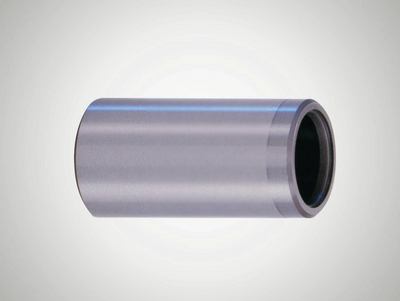

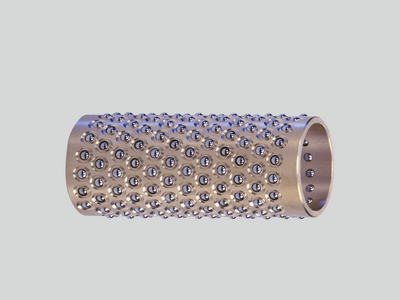

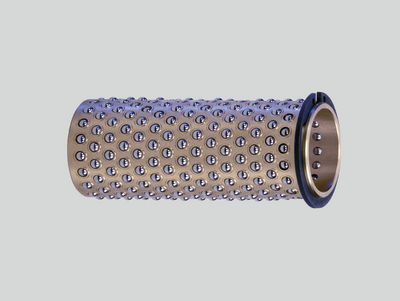

Ball-bearing guides for linear and rotational movements without play for use in all technical areas where reliability and precision are required.

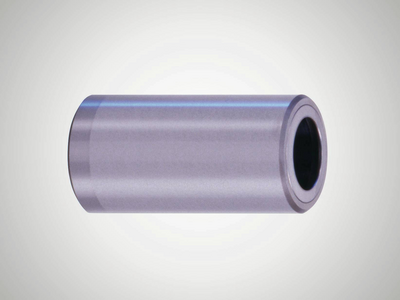

The guide diameter finely honed to ISO tolerance IT 3 guarantees the preload of the ball bearing guide in combination with shaft diameter ISO-h3.

Universal, slim inner bevels on both sides.

Permanently installed thrust washers on both sides provide a safe travel limit for the ball cage.

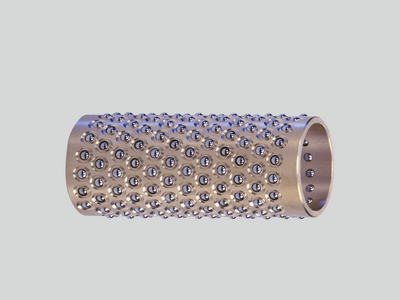

Permanently installed thrust washers on each side and sealing rings prevent impurities from getting into the ball bearing guide.

Extra sturdy model with scrapers on both sides which reliably prevent impurities from getting in, even in very dirty environments.

Universal, slim inner bevels on both sides, for use with ball cage from mini series N502.

Permanently installed thrust washers on both sides provide a safe travel limit for the ball cage from mini series N502.

The balls can move easily without getting lost. The balls are arranged in such a way that they run smoothly and ensure a long service life of the ball bearing guide.

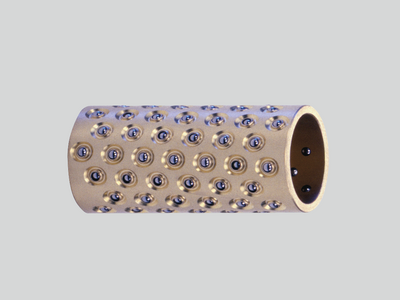

Excellent dry run properties and maximum smoothness, even at high accelerations thanks to the lightweight plastic.

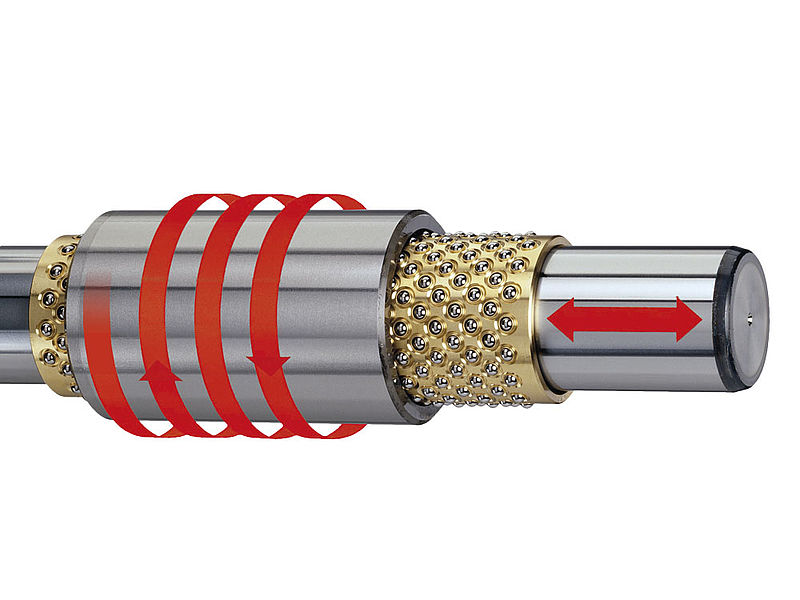

Versatile with balls arranged along a helical line, ideal for linear movements and rotational movements.

Smaller balls used with same shaft diameter compared to type N501. Reduced installation space thanks to guide bushes from the mini series.

High loading capacity thanks to large number of balls, reliable travel limit for the cage thanks to the securing ring.

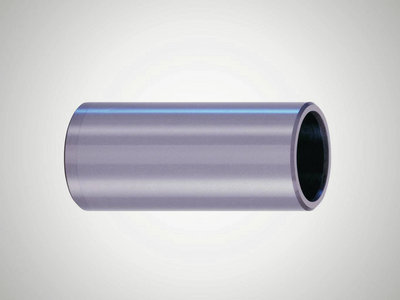

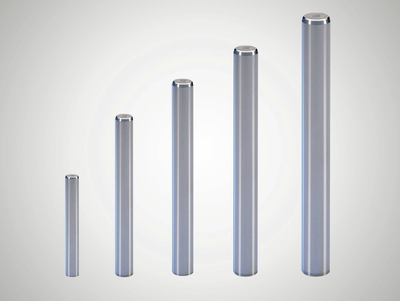

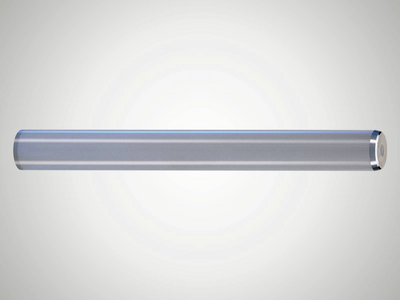

The finely-ground surface is ideal for high precision ball bearing guides, ensuring smooth running and a long service life of the ball bearing guide.

Preload is guaranteed when using with Mahr guide bushes and ball cages.

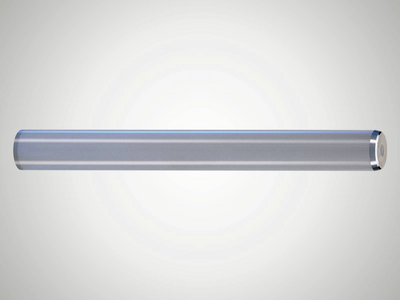

Inner thread on both sides, preload is guaranteed when using with Mahr guide bushes and ball cages.

Broader and more optimized range of uses.

Protect open ball-bearing guides against dirt without compromising smooth movement.

Lubrication for maximum performance and corrosion prevention.

For all types of rotational and linear movements

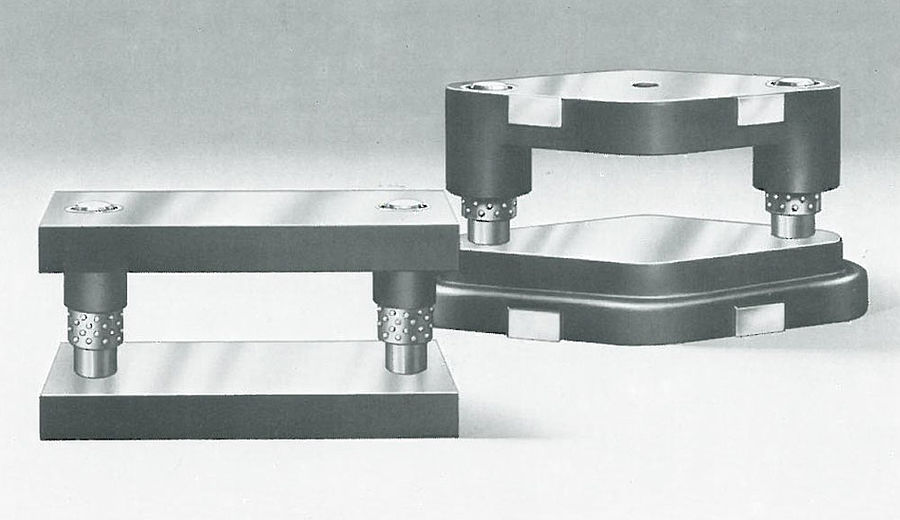

Mahr has established itself in the measurement technology sector. The sense of precision is also present in the MarMotion ball-bearing guides – ball-bearing guides that come with experience, innovation and commitment. The precision machining of hardened steels is one of Mahr's key skills. It is based on the experience gained during the production of precise measuring tools and instruments and the manufacture of gear metering pumps. On this basis, Mahr's ball-bearing guides are also being developed further and optimized. Today, MarMotion ball-bearing guides are universally applicable in mechanical engineering and precision engineering for all types of rotational and linear movements.

Application-specific solutions

We supply our customers with application-specific solutions. For this purpose, a standardized catalog range of ball-bearing guides is available, which can be added to with customer-specific solutions if required. The entire range is covered, from one-off productions to small and medium-sized series and large series.

Mahr would like to talk to you: We get to know your application and work with you to find a technically optimized and cost-effective solution. Your contact partners are our product specialists for ball-bearing guides, who, as experienced technicians and engineers, work closely with Mahr production drawing on experience from a wide variety of applications – Mahr offers you more than just a product!

Your benefits

- Guide accuracy for accurate movements

- Functional safety

- Both stroke and rotational movements

- Hardened steels

- Exact calculation bases

- Individual consultation

- Certified production and order processing

Your advantages

- Individual solutions for your applications

- Long service life of the ball-bearing guides

- Thus optimizing the cost of systems

- Optimizing our customers' processes

Success with a large team

40 employees generate a turnover of EUR 6 million

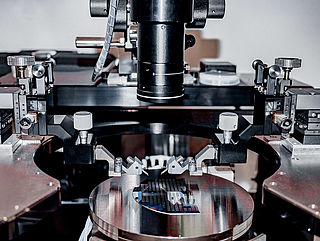

Cleanroom cell

Mahr installs a cleanroom cell to supply a manufacturer of tape drives in the USA with very large quantities of ball-bearing guides.

A new name

A new product name for the ball-bearing guides is being used in catalogs: In keeping with the company philosophy, the product now had a new name: "MarMotion high-precision ball-bearing guides".

Sharply increasing quantities

Quantities are rising sharply. The production of ball cages was thus relocated to the Czech Republic – to the same company that also manufactured hand-held measuring equipment for Mahr. The ball-bearing guides are assembled and the final check is performed, in Göttingen, Germany.

New machinery

Modern new machinery with external cylindrical grinders, lathes and drills is set up for the production of the ball-bearing guides.

Increase

Strong increase in the quantities

A department is created

For the first time, an employee at Feinprüf/Mahr is focuses solely on ball-bearing guides

International market success

In the 1960s/1970s, the ball-bearing guides were an international commercial success. A first catalog for the Asian market is published

Own product group

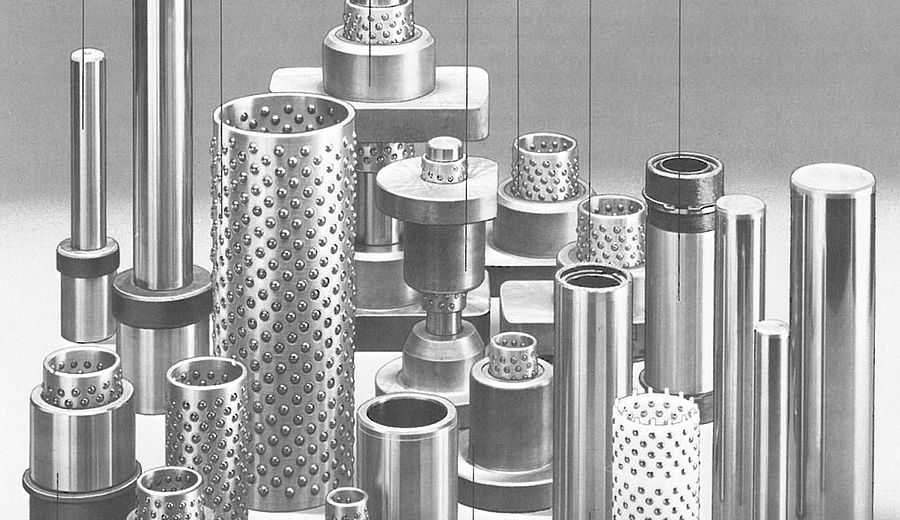

Ball-bearing guides become a separate product group at Feinprüf/Mahr. Due to the precision of the cages Suppliers of the punching and forming industry sector as well as plant engineers for lathes. First product catalog only for ball-bearing guides

Ball-bearing guides for punching tools

Post-war period: Installation of the first ball-bearing guides in punching tools at Feinprüf/Mahr to accurately repeat the punching and cutting of punched parts made of sheet metal, in the printing and textile industry without canting