High-quality metrology for quality control in the measuring room, production, incoming goods and development.

Gear Metering Pumps & Meter Mix Dispense Machines with highest accuracy for processing liquids and pastes.

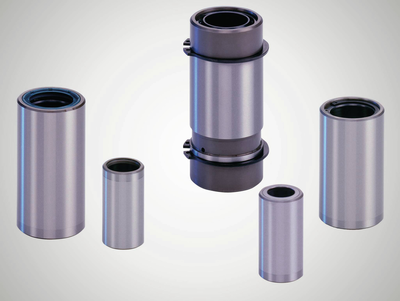

High-precision rotary stroke bearings for backlash-free linear and rotational movements for use in machine and device construction.

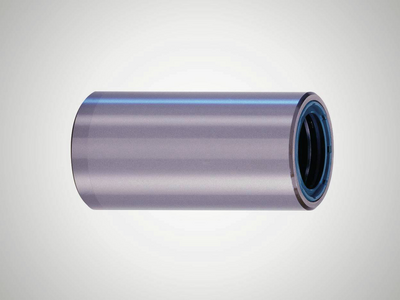

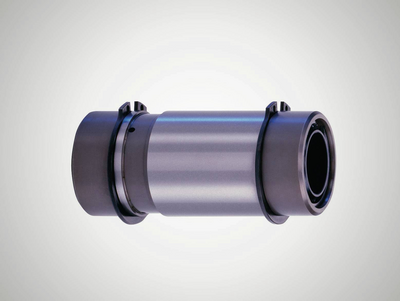

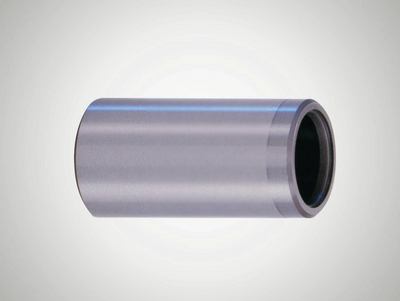

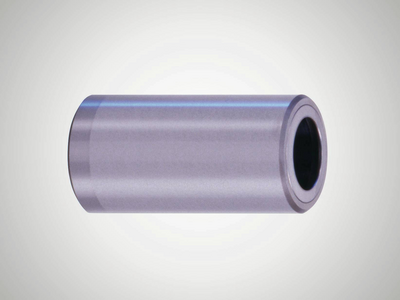

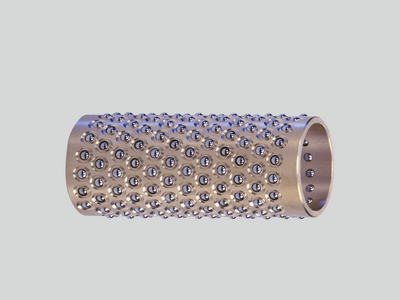

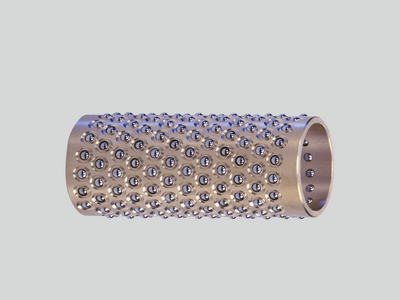

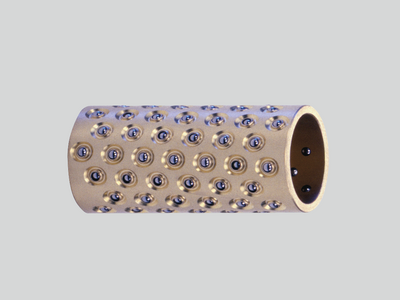

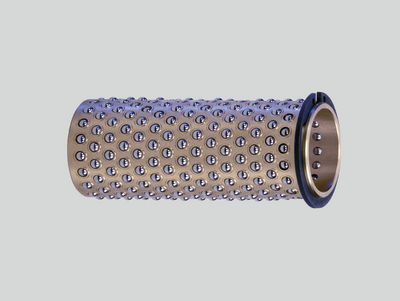

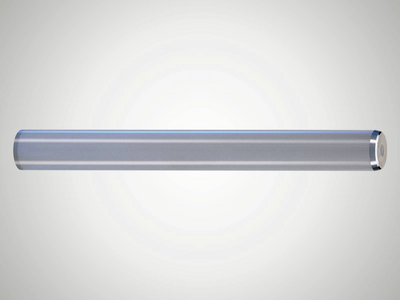

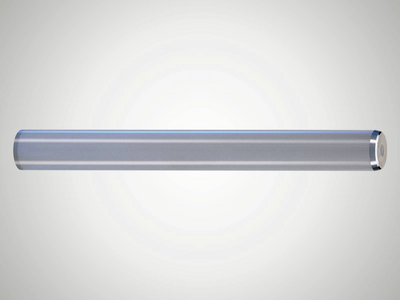

Ball-bearing guides for linear and rotational movements without play for use in all technical areas where reliability and precision are required.

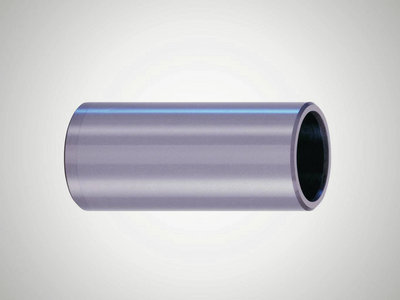

The guide diameter finely honed to ISO tolerance IT 3 guarantees the preload of the ball bearing guide in combination with shaft diameter ISO-h3.

Universal, slim inner bevels on both sides.

Permanently installed thrust washers on both sides provide a safe travel limit for the ball cage.

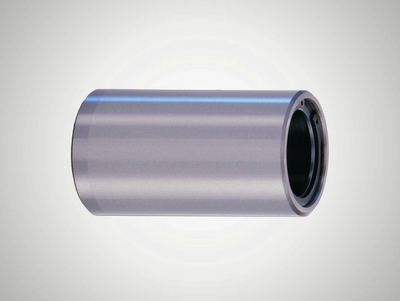

Permanently installed thrust washers on each side and sealing rings prevent impurities from getting into the ball bearing guide.

Extra sturdy model with scrapers on both sides which reliably prevent impurities from getting in, even in very dirty environments.

Universal, slim inner bevels on both sides, for use with ball cage from mini series N502.

Permanently installed thrust washers on both sides provide a safe travel limit for the ball cage from mini series N502.

The balls can move easily without getting lost. The balls are arranged in such a way that they run smoothly and ensure a long service life of the ball bearing guide.

Excellent dry run properties and maximum smoothness, even at high accelerations thanks to the lightweight plastic.

Versatile with balls arranged along a helical line, ideal for linear movements and rotational movements.

Smaller balls used with same shaft diameter compared to type N501. Reduced installation space thanks to guide bushes from the mini series.

High loading capacity thanks to large number of balls, reliable travel limit for the cage thanks to the securing ring.

The finely-ground surface is ideal for high precision ball bearing guides, ensuring smooth running and a long service life of the ball bearing guide.

Preload is guaranteed when using with Mahr guide bushes and ball cages.

Inner thread on both sides, preload is guaranteed when using with Mahr guide bushes and ball cages.

Broader and more optimized range of uses.

Protect open ball-bearing guides against dirt without compromising smooth movement.

Lubrication for maximum performance and corrosion prevention.

Backlash-free linear and rotary movements

Precise and reliable: The precision guides made of hardened steel master movements at the highest repeatability with minimal maintenance work, and a long service life. This optimizes costs and production processes. Machines and equipment are more reliable and efficient.

Rotary stroke bearings for machine building

MarMotion rotary stroke bearings achieve robustness and durability in numerous applications with their low maintenance requirements even under difficult environmental conditions. Closed designs with sealing rings or wiper seals are used. This results in innovative, new designs for challenging applications in the automation sector, machine tools, packaging machines or bottling plants. Adapted designs ensure that the requirements of the food industry are also met.

Mahr offers you more than just a product.

Our expertise creates benefits in the automotive industry, mechanical and electrical engineering, as well as in medical technology, optics or aerospace. Our solutions speak the language of many branches of industry, the language of quality, safety and sustainability.

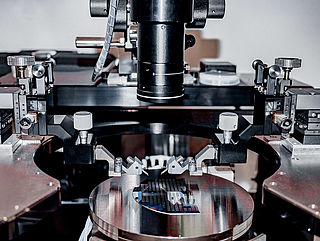

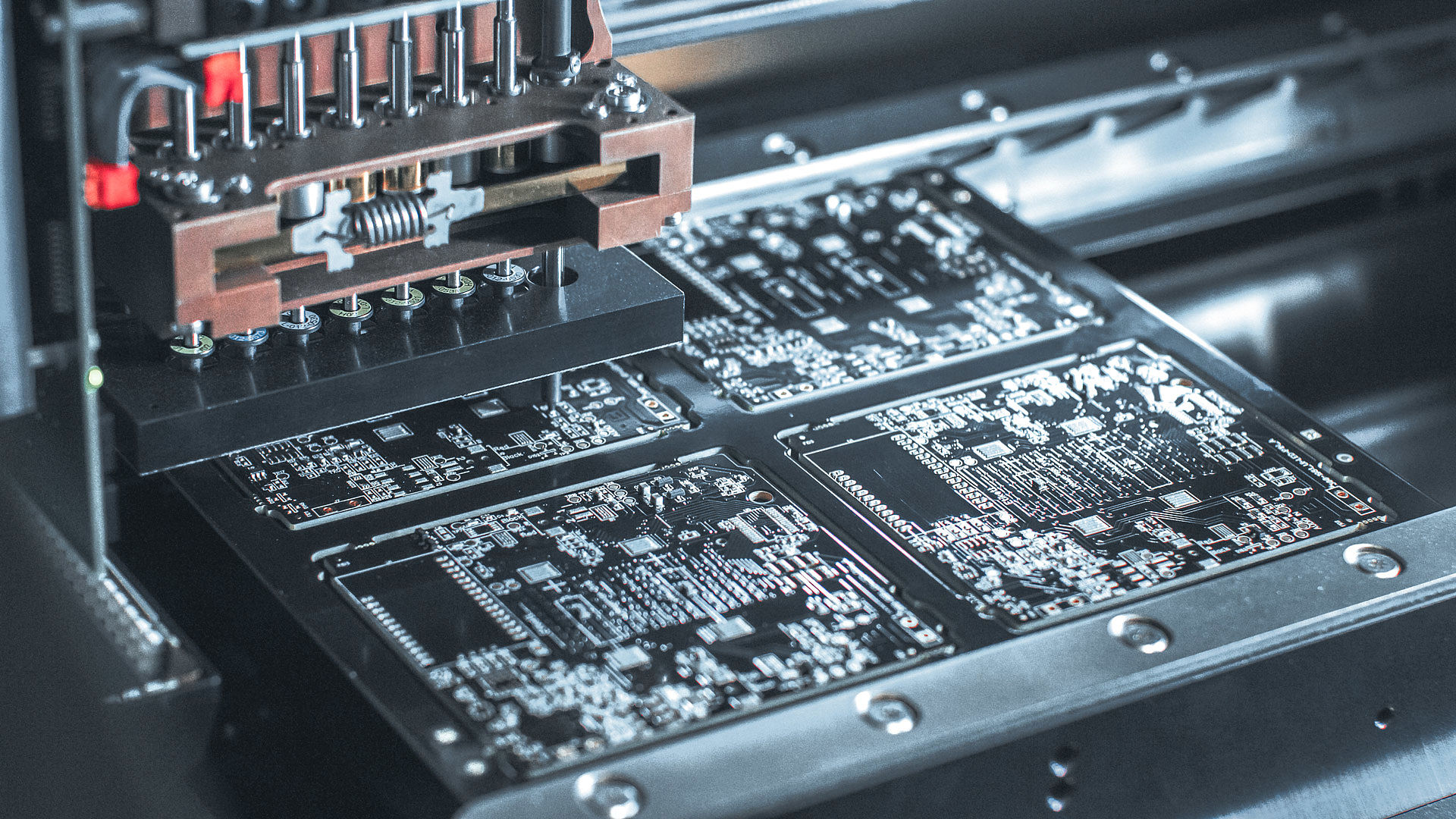

Precision bearings for electronics manufacturing, precision engineering and optics

The rotary stroke bearing combines precision and rigidity in a unique way with compact dimensions. A special mini-range is available. Selected materials that enable the use in a vacuum or cleanroom are available upon request. Dry running is also possible in many of the applications. MarMotion rotary stroke bearings provide outstanding services in optics for microscopes, beam control systems in laser technology or pick-and-place systems in the electronics and semiconductor production. This is where the Mahr rotary stroke bearing demonstrates its strengths.

Features

Maximum guiding accuracy

The MarMotion rotary stroke bearings offer a very high level of guiding accuracy for linear and rotary movements. This is achieved by finely machined surfaces of the guide shaft and guide bush, for which the form accuracy in terms of roundness and cylindricity is within 1/3 of ISO tolerance class IT 3, as well as by only using steel balls in quality grade 5, type N in accordance with DIN 5401 or ISO 3290.

Backlash-free movements

The gap between the guide bush and guide shaft is a few µm smaller than the diameter of the balls, so that the balls deflect slightly. The preloaded balls roll without slip between the guide shaft and guide bush and ensure that the guide is free of backlash. The optimum preload is set at the factory by pairing of the guide shaft, ball cage, and guide bush. This simplifies the installation of the bearing.

Smooth running

MarMotion rotary stroke bearings enable the highest guiding accuracy in combination with extremely low friction. A slip-free rolling movement of the balls on finely machined surfaces results in very low friction values and ensures smoothest, stick-slip-free motions.

High loading capacity and rigidity

The large number of balls with tight form tolerances and the excellent quality of the running surfaces of the MarMotion rotary stroke bearings provide a large number of contact points and thus an even distribution of forces in the bearing. Design engineers benefit from a high loading capacity in a small installation space. Reliability and endurance of the bearing is significantly increased.

Fast movements, high accelerations

Fast movements with high accelerations are possible due to the slip-free rolling movement of the balls at lowest friction in the MarMotion rotary stroke bearings. Due to their lower inertia forces, plastic ball cages are particularly suitable for high-frequency rotational and linear movements.

Long service life

MarMotion rotary stroke bearings can be described as virtually wear-free thanks to the careful selection and heat treatment of the materials and the highest quality of the running surfaces.

Low maintenance

In most cases, a thin film of roller bearing grease is sufficient for months of maintenance-free, continuous operation.

Exchange and replacement

The high-precision production of the guide shaft and guide bush, the exclusive use of grade N balls and a continuous quality assurance ensure the interchangeability of the rotary stroke bearing. Permanent fault-free operation is guaranteed.

Customized Designs

The very extensive catalog range of MarMotion rotary stroke bearings offers suitable solutions for use in many different application areas. In addition, customized designs based on a workpiece drawing can be produced for specific applications and to meet particular requirements. The use of alternative materials opens up even further possibilites.