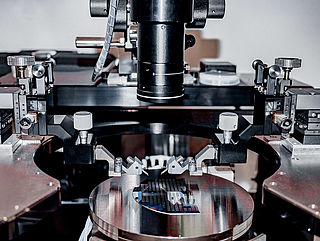

High-quality metrology for quality control in the measuring room, production, incoming goods and development.

Gear Metering Pumps & Meter Mix Dispense Machines with highest accuracy for processing liquids and pastes.

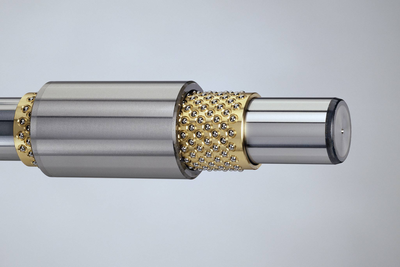

High-precision rotary stroke bearings for backlash-free linear and rotational movements for use in machine and device construction.

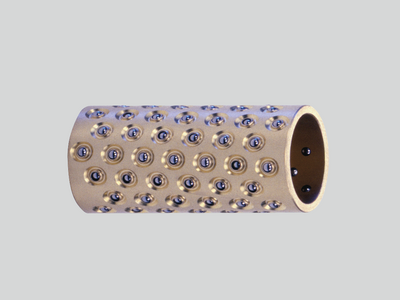

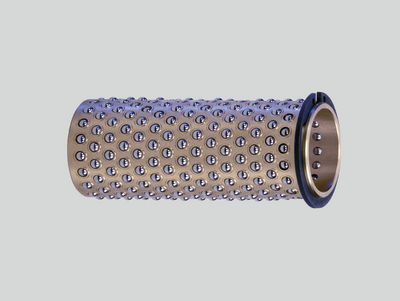

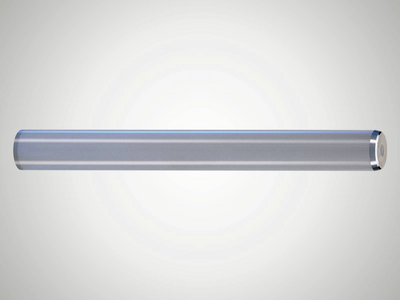

Ball-bearing guides for linear and rotational movements without play for use in all technical areas where reliability and precision are required.

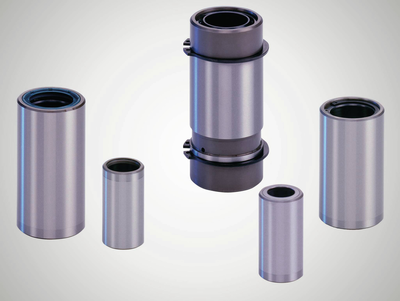

The guide diameter finely honed to ISO tolerance IT 3 guarantees the preload of the ball bearing guide in combination with shaft diameter ISO-h3.

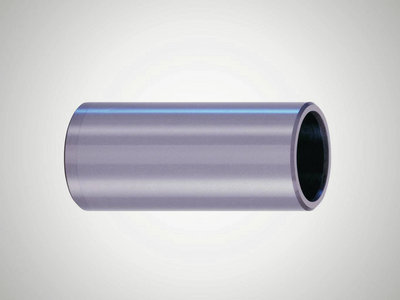

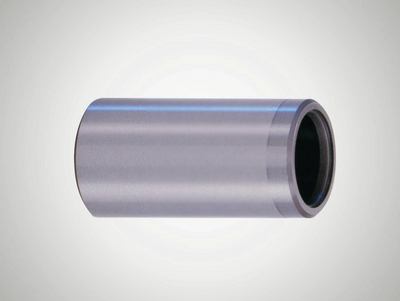

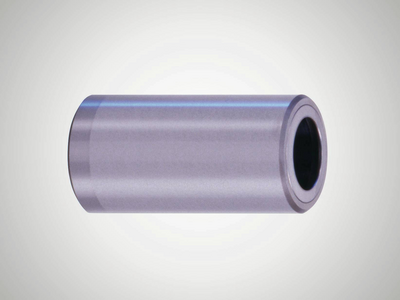

Universal, slim inner bevels on both sides.

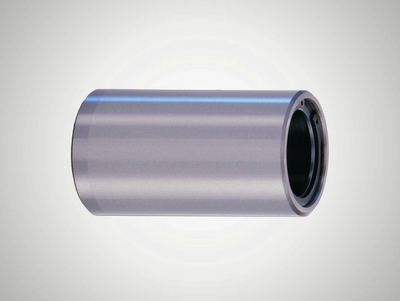

Permanently installed thrust washers on both sides provide a safe travel limit for the ball cage.

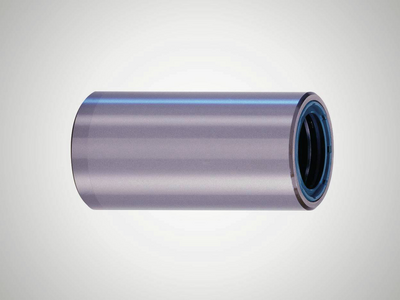

Permanently installed thrust washers on each side and sealing rings prevent impurities from getting into the ball bearing guide.

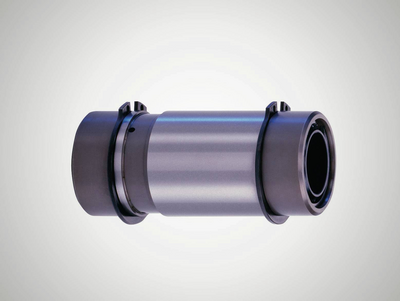

Extra sturdy model with scrapers on both sides which reliably prevent impurities from getting in, even in very dirty environments.

Universal, slim inner bevels on both sides, for use with ball cage from mini series N502.

Permanently installed thrust washers on both sides provide a safe travel limit for the ball cage from mini series N502.

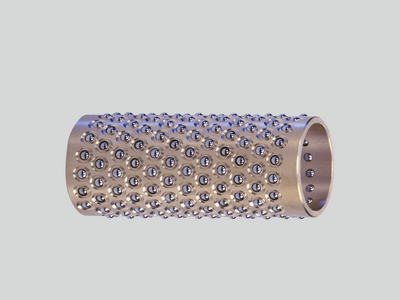

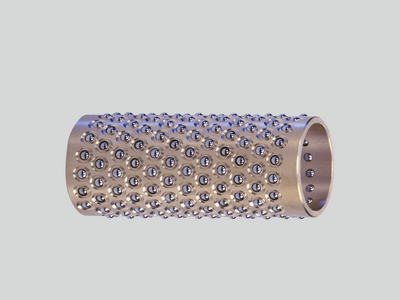

The balls can move easily without getting lost. The balls are arranged in such a way that they run smoothly and ensure a long service life of the ball bearing guide.

Excellent dry run properties and maximum smoothness, even at high accelerations thanks to the lightweight plastic.

Versatile with balls arranged along a helical line, ideal for linear movements and rotational movements.

Smaller balls used with same shaft diameter compared to type N501. Reduced installation space thanks to guide bushes from the mini series.

High loading capacity thanks to large number of balls, reliable travel limit for the cage thanks to the securing ring.

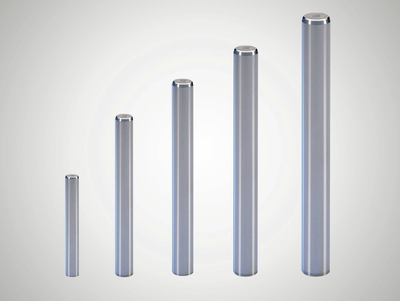

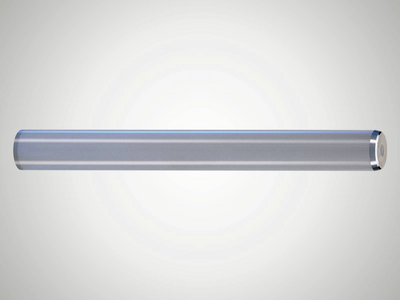

The finely-ground surface is ideal for high precision ball bearing guides, ensuring smooth running and a long service life of the ball bearing guide.

Preload is guaranteed when using with Mahr guide bushes and ball cages.

Inner thread on both sides, preload is guaranteed when using with Mahr guide bushes and ball cages.

Broader and more optimized range of uses.

Protect open ball-bearing guides against dirt without compromising smooth movement.

Lubrication for maximum performance and corrosion prevention.

Questions and answers

CAD data is available for all of the components in STEP format in the online product catalog. Select an item. In the detail view, under the Download tab you can opt to have the required data sent to your e-mail address – easy and without registraton.

The outer diameter dB of type N550, N552 and N553 guide bushes are manufactured with ISO tolerance n4, while type N570 has an ISO tolerance h6.

An interference fit can damage the guide bush. The installation bore should therefore be tolerated in a way that an interference fit is avoided (e.g. n4/E6).

The guide bush can also be glued in place. The installation bore must then be dimensioned in such a way that a suitable adhesive gap is formed. The instructions provided by the adhesive manufacturer must be observed. An adhesive with a curing time that is not too short is recommended.

Generally, greases and oils that are suitable for lubricating roller bearings are also suitable for rotary stroke bearings. The selection is made based on the operating conditions (e.g. temperature, speed, ambient media). Grease should be used very sparingly. Solid lubricants are not suitable. In special cases, dry running is also possible.

A MarMotion rotary stroke bearing, which is appropriately dimensioned and free of abrasive particles and corrosion during operation, is virtually free of wear. Depending on the operating conditions, lifetime lubrication or lubrication by a central lubrication systems are possible. Maintenance can be carried out within the standard maintenance intervals.

MarMotion rotary stroke bearings generally work under preload, i.e. completely backlash-free. The gap between the guide bush and the guide shaft is smaller than the ball diameter. The balls are under tension. The exact preload setting is decisive for the running properties of the rotary stroke bearing. A low preload improves the smoothness of the motion, while a higher preload increases the rigidity.

A preload that is changed by just a few micrometers can fundamentally change the properties of the rotary stroke bearing. Due to tight production tolerances, the components can be replaced. It is recommended to order complete sets of rotary stroke bearings consisting of a guide bush, ball cage and guide shaft, so that an optimum preload can be set at the factory.

The inner diameter of the guide bush is tolerated in such a way that in combination with the diameter of the guide shaft in ISO tolerance h3 an appropriate preload of the rotary stroke bearing is determined. If necessary, the diameter of the guide shaft and the inner diameter of the guide bush are adjusted at the factory to achieve an optimum preload. If ordered as a complete set, the rotary stroke bearing will be delivered as an assembly consisting of a guide bush, ball cage and guide shaft.

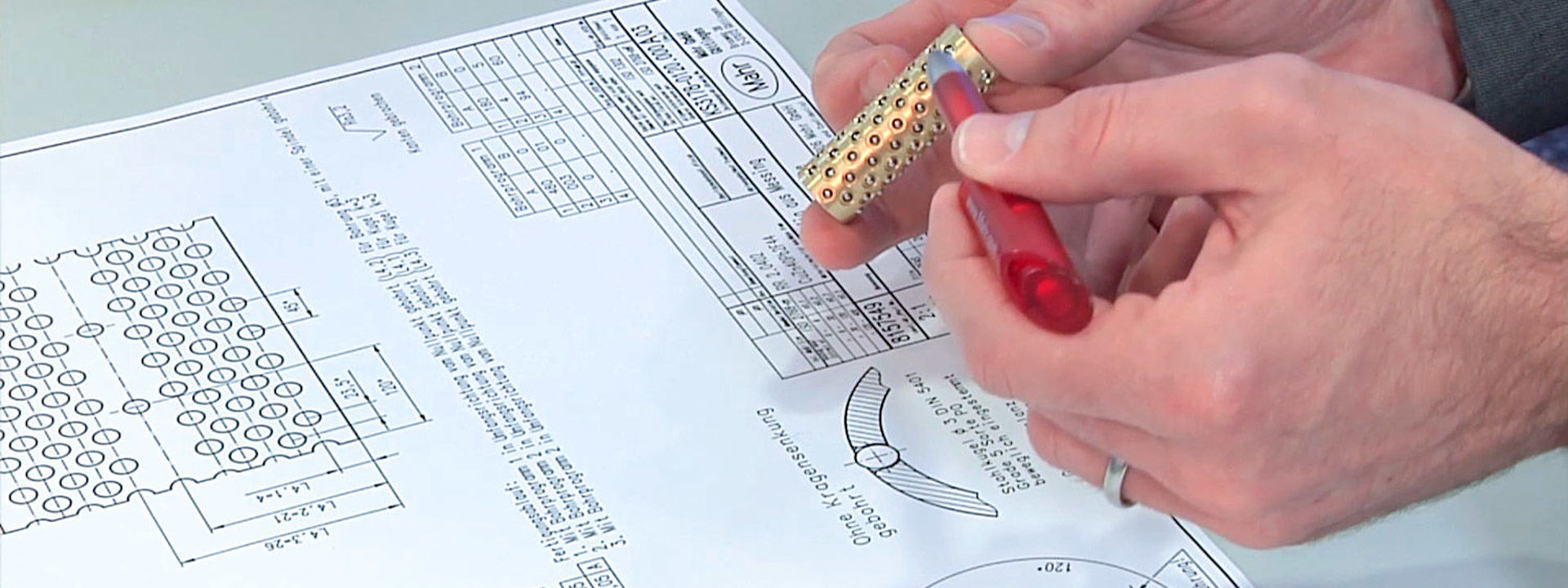

All components can be made according to customer drawings upon request, e.g:

Guide bush:

- Special lengths and diameters

- Recesses

- Flange

Ball cage:

- Special lengths and diameters

- Other ball diameter or number of balls

- Ball arrangement, e.g. in ball zones

- Ball Cage with circlip

- Axial cage

Guide shaft:

- Special lengths and diameters

- Internal thread / external thread

- Flange

- Sleeve shafts

Guides bushes, guide shafts and balls are made of hardened 100Cr6 roller bearing steel (1.3505). Stainless steel versions (e.g. 1.4112) can be supplied as special designs upon request. The balls in the type N502 ball cage are generally made of stainless steel.

Ball cages with ceramic balls are available as special design upon request.

Ball cages are made of brass or plastic (POM). Cages made of aluminum, bronze or selected plastic materials (e.g. PEEK) are available as special designs.

The type N553 guide bush is equipped with sealing rings, type N570 with wiper seals. Alternatively, bellows can be used, e.g. type N820 leather bellows.

With a MarMotion rotary stroke bearing that has been adequately dimensioned (P10 ≤ C10), the material is only loaded within the fatigue limit. Provided that the bearing is free of abrasive particles and corrosion, this results in a virtually unlimited service life.

The load must be less than or equal to the loading capacity of the rotary stroke bearing. For a uniform radial load, loading capacities of the ball cages can be found in the online catalog. The online product selector will help you to select suitable components. Simply enter the dimensions or the load. Intelligent filters show you how to find a suitable combination of rotary stroke bearing components. In the event of an uneven radial load or moment, the equivalent radial load must be calculated.