Gear Metering Pumps & Meter Mix Dispense Machines with highest accuracy for processing liquids and pastes.

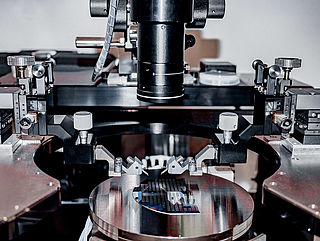

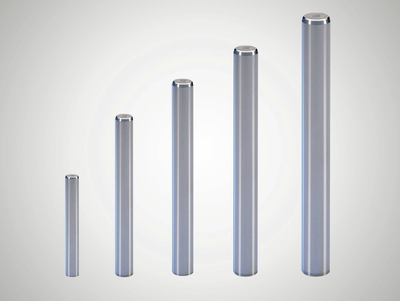

High-precision rotary stroke bearings for backlash-free linear and rotational movements for use in machine and device construction.

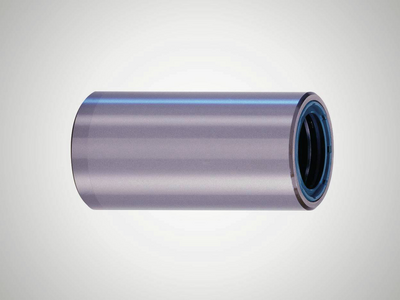

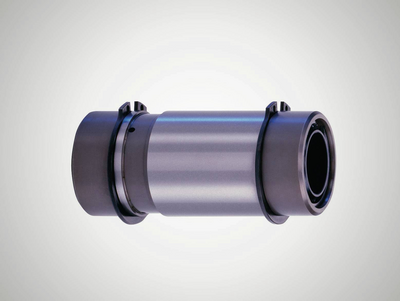

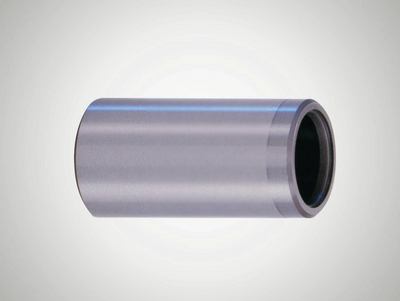

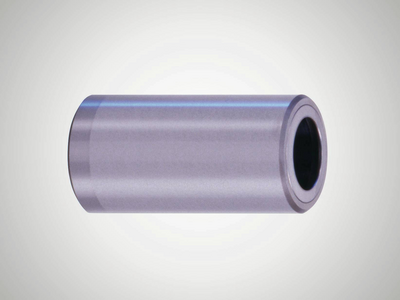

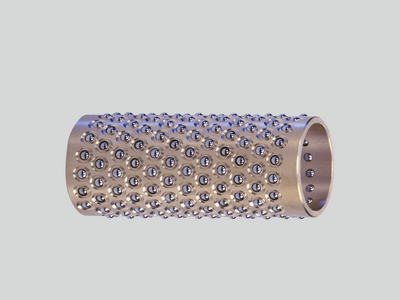

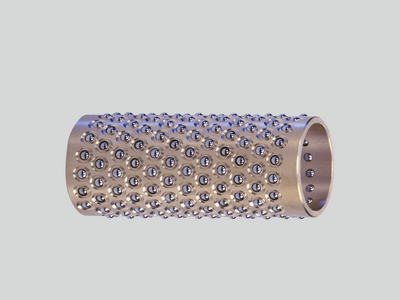

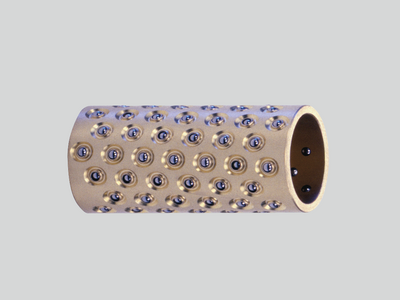

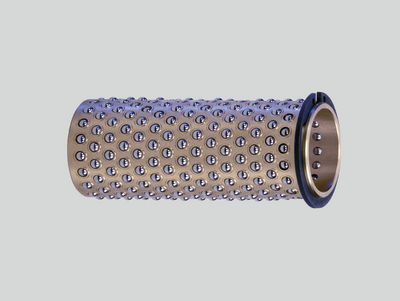

Ball-bearing guides for linear and rotational movements without play for use in all technical areas where reliability and precision are required.

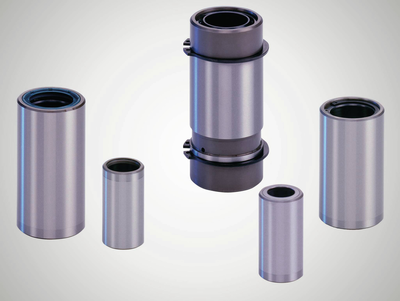

The guide diameter finely honed to ISO tolerance IT 3 guarantees the preload of the ball bearing guide in combination with shaft diameter ISO-h3.

Universal, slim inner bevels on both sides.

Permanently installed thrust washers on both sides provide a safe travel limit for the ball cage.

Permanently installed thrust washers on each side and sealing rings prevent impurities from getting into the ball bearing guide.

Extra sturdy model with scrapers on both sides which reliably prevent impurities from getting in, even in very dirty environments.

Universal, slim inner bevels on both sides, for use with ball cage from mini series N502.

Permanently installed thrust washers on both sides provide a safe travel limit for the ball cage from mini series N502.

The balls can move easily without getting lost. The balls are arranged in such a way that they run smoothly and ensure a long service life of the ball bearing guide.

Excellent dry run properties and maximum smoothness, even at high accelerations thanks to the lightweight plastic.

Versatile with balls arranged along a helical line, ideal for linear movements and rotational movements.

Smaller balls used with same shaft diameter compared to type N501. Reduced installation space thanks to guide bushes from the mini series.

High loading capacity thanks to large number of balls, reliable travel limit for the cage thanks to the securing ring.

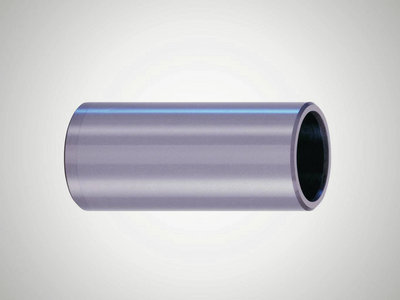

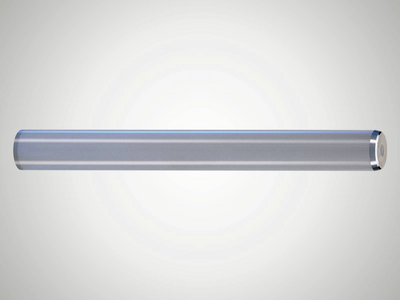

The finely-ground surface is ideal for high precision ball bearing guides, ensuring smooth running and a long service life of the ball bearing guide.

Preload is guaranteed when using with Mahr guide bushes and ball cages.

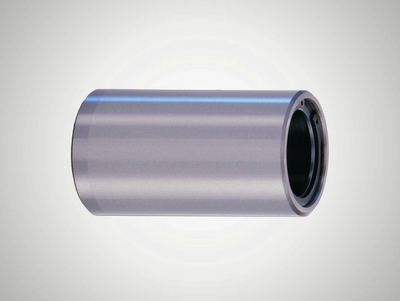

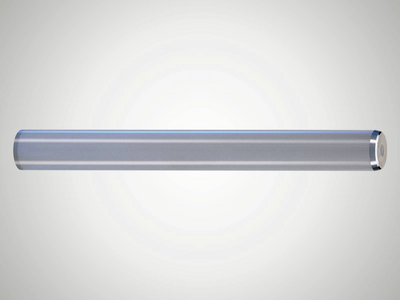

Inner thread on both sides, preload is guaranteed when using with Mahr guide bushes and ball cages.

Broader and more optimized range of uses.

Protect open ball-bearing guides against dirt without compromising smooth movement.

Lubrication for maximum performance and corrosion prevention.

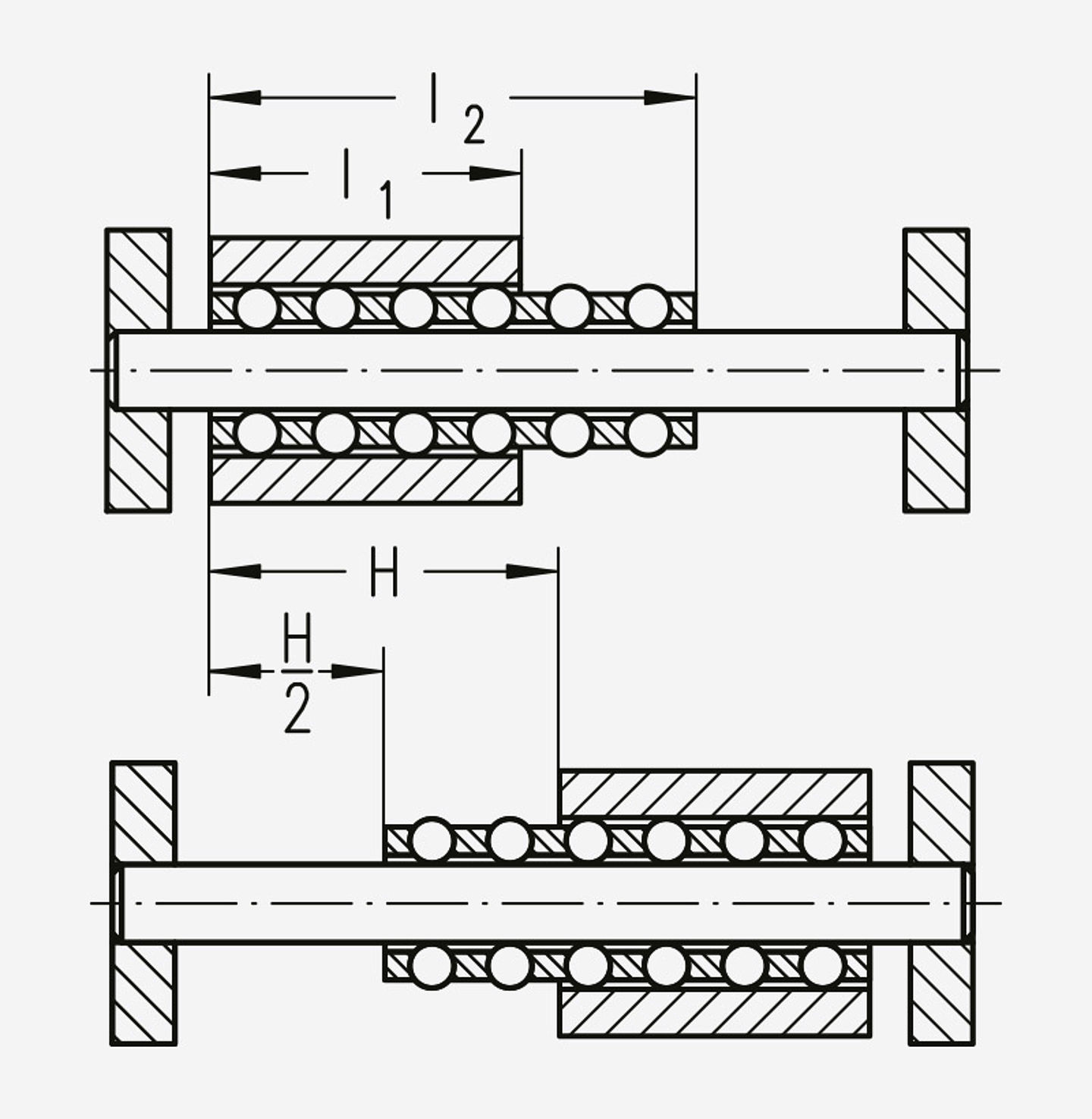

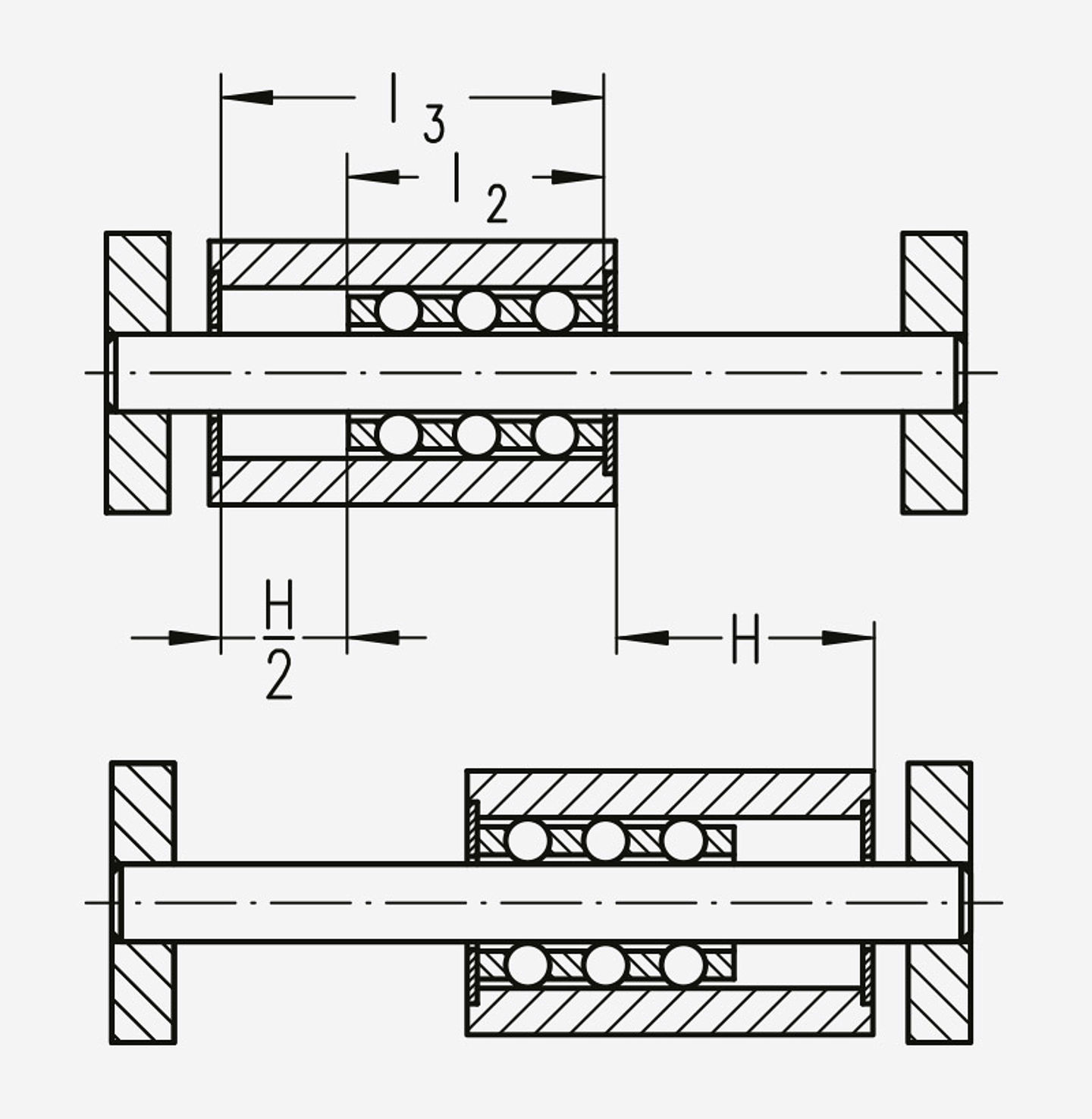

Length of stroke and contact length

The contact length is determined by the position of the guide bush, ball cage and guide shaft towards each other in the end positions of the linear movement. There are two different modes of operation.

Open guide bush<br/> Cage length L2 can be longer than or equal to guide bush length L1.<br/> Max. linear movement: H = 2 (L2 – L1)

Closed guide bush<br/> Bushing length L3 is longer than cage length L2, the ball cage remains within the guide bush.<br/> Max. linear movement: H = 2 (L3 – L2)

For both modes of operation, the aim is to achieve a constant contact length E over the entire linear movement. This is always the case with closed rotary stroke bearings. With open rotary stroke bearings, the bushing should be flush with the cage in the end positions of the linear motion. If the bushing extends beyond the end of the cage, the contact length and thus the loading capacity of the rotary stroke bearing is reduced in this position.

The shortest permissible ball contact length E is determined by the required loading capacity. The load ratings of the ball cages can be used as guide values.

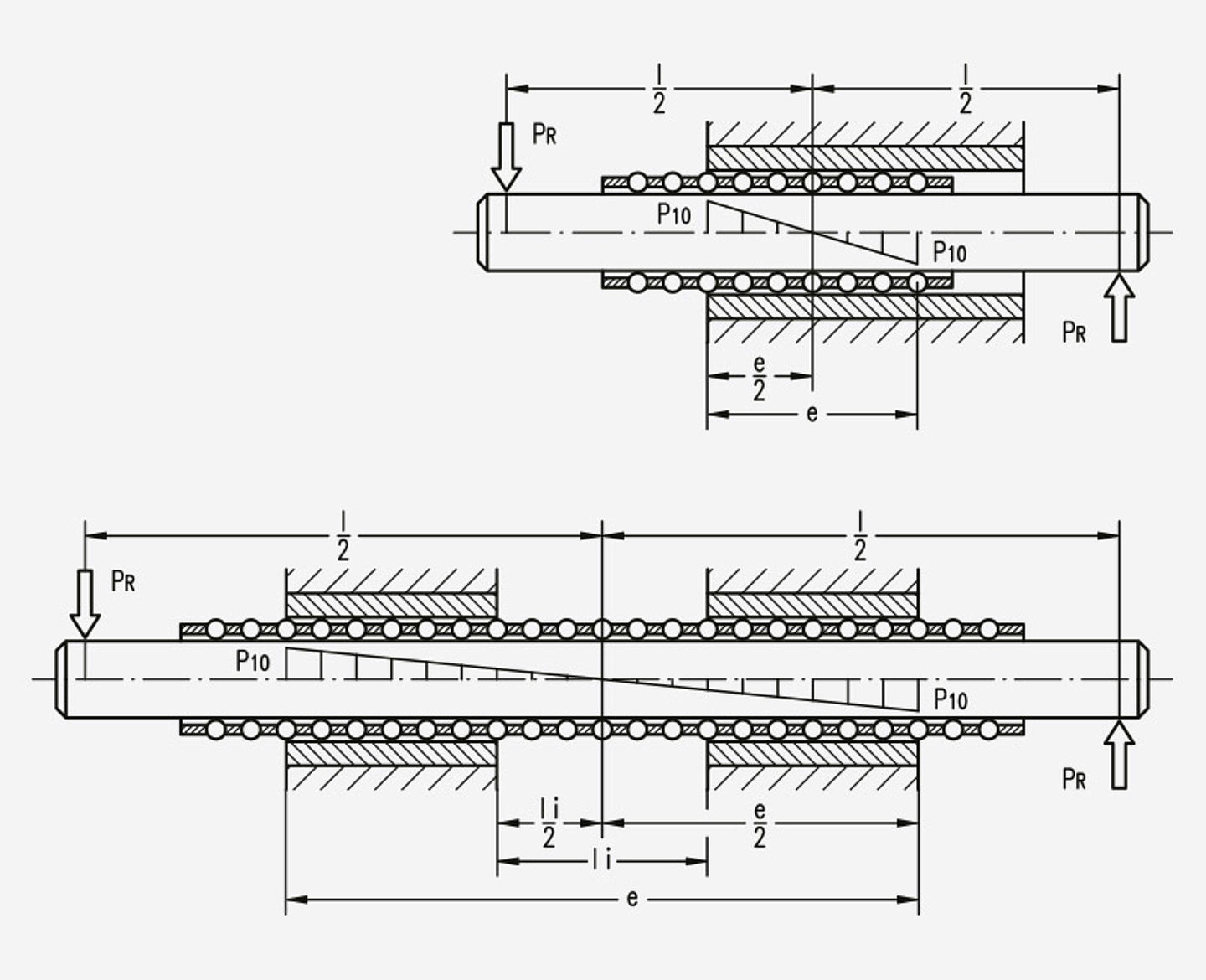

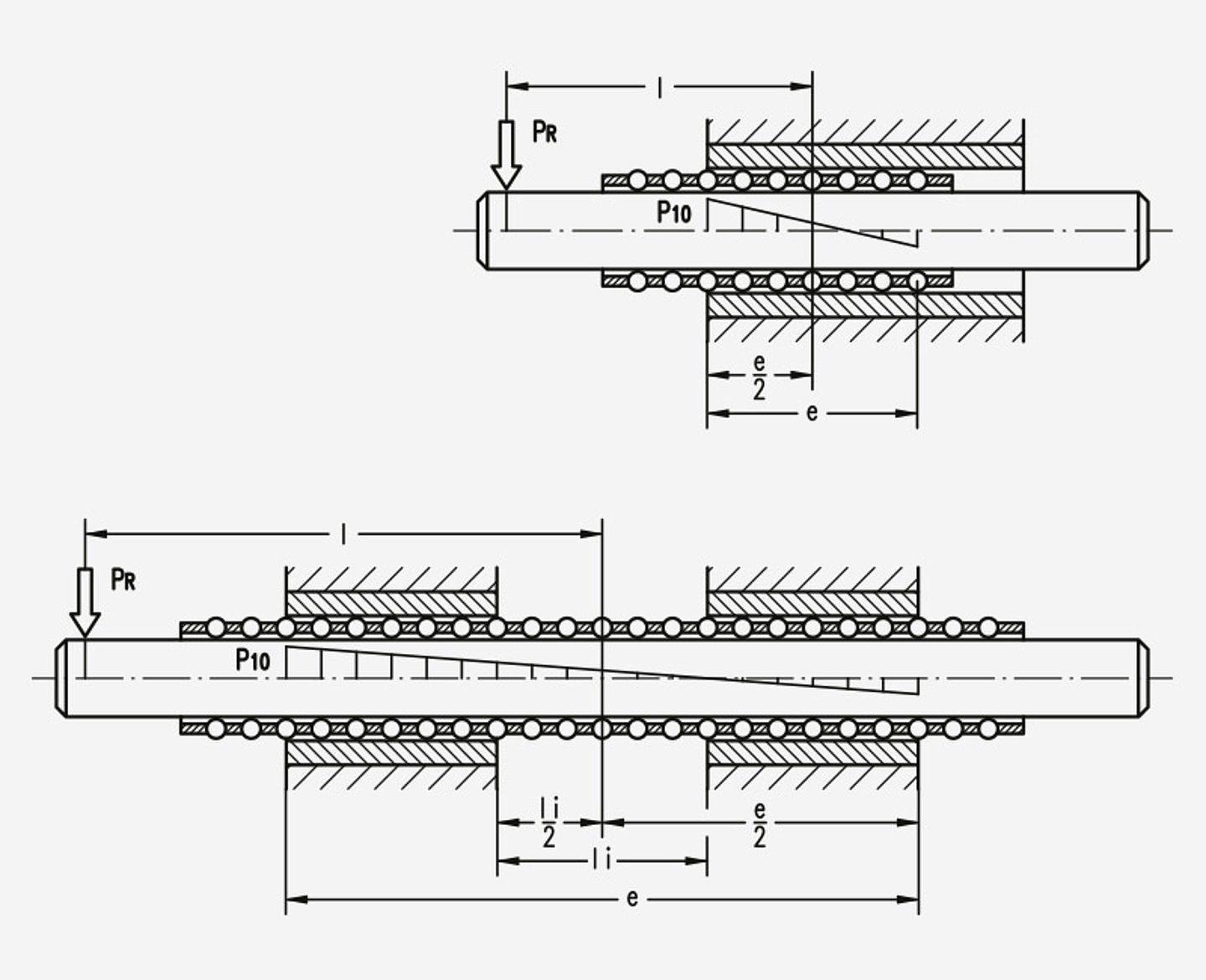

Reference contact length e

To calculate a rotary stroke bearing, it is always necessary to determine the reference contact length e = ball contact length in the case of unfavorable load distribution.

At a low load

For rotary stroke bearings used for precise guidance without a significant load, the following values E are recommended depending on dw: see table.